Beginner's Guide to 3D Printing

While the concept of 3D printing may still seem rather futuristic, the reality is that the technology has been around since the 1980s. 3D printing has seen something of a resurgence in recent years and gained significant popularity as it continues to develop and mature.

Many industires, like the fashion industry, have adopted the technology and are using it for many interesting applications. follow us on Instagram, Facebook and Twitter for updates on the latest in 3D printing news!

What is 3D printing?

This technology – which we refer to as 3D printing – is actually a family of technologies, that employ similar but different methods to build objects by adding material layer by layer, it all begins with a digital file that can be produced through 3D modeling on CAD software or through 3D scanning of existing objects. The file is then sliced and sent to the 3D printer, where the printer reads each slice and builsd the object. There are multiple types of 3D printers available today, as shown below. this guide will briefly goover some of them. Let’s get started.

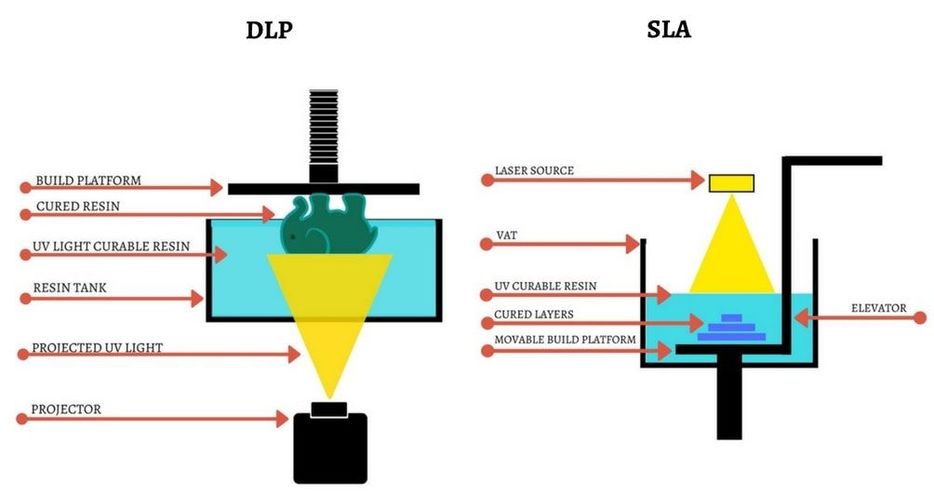

Vat Polymerization

This category of 3D printers utilize a vat of liquid photo-polymer resin that can be cured with a light source. Stereolithography (SLA) holds the distinction of being the first 3D printing technology. It was developed in 1986 by American engineer Chuck Hull. SLA uses a focused laser point to cure the resin one layer at a time. Another type of vat polymerization is Digital Light Processing (DLP), which uses a digital light projection to cure the entire layer at once. A comparision is shown below.

Material Extrusion

The most well known and commonly available form of 3D printing is Fused Deposition Modeling (FDM). This is the technology that is used in many popular 3D printers like the MakerBot Replicator for example, a thromoplastic filament usually ABS or PLA, is heated and pushed through a nozzle onto the printer bed where it cools and adheres to any previous layers. Think of this like a very accurate ad precise hot glue gun.

Powder Bed Fusion

This is the technology that 3dEnginEarrings uses for our jewelry. The printer puts down a layer of powdered material and a heat source fuses the particles into a solid. Most of the time, a laser is used as the heat source. this is the case for Selective Laser Sintering (SLS) of thermoplastic powders, as well as for Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) for metal powders. The difference between DMLS and SLM lies in the degree of melting of the metal particles. For metal powders, an electron beam is sometimes used instead as the heat source (EBM).

Binder Jetting

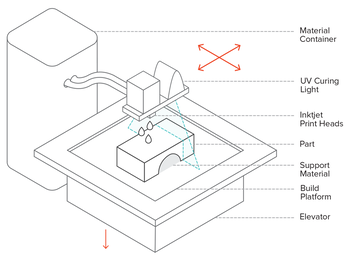

Material Jetting

Similar to Powder Bed Fusion technologies, Binder Jetting (BJ) also uses a bed of powdered material. However, a bonding material is used to fuse the particles instead of a heat source.

In Material Jetting (MJ), droplets a photo-polymer resin are deposited on the print surface and cured with UV light. You can think of this like an inkjet printer that prints so many layers that the result in 3D.

3D Printing and the Fashion Industry

3D ptinting is becoming very important in many industries, including the fashion world, as it reshapes the way we all look at manufacturing. There are many advantages to 3D printing, including the fact that it doesn’t require any tooling. Traditionally, designers are limited to what they can do with patterns, stitching, molds, and other techniques. 3D printing gives them the freedom to be more creative during their design process.

3D printed textiles are constantly being improved and are at the point where dresses, bikinis, and even shoes are being created. Many designers are already sending 3D printed haute couture down the runaways. In the jewlry industry, 3D printing is often used to create molds for complex designs. It is also starting to be used more to produce the actual jewlery itself, basically what we do here at 3dEnginEarrings.

Hopefully you’ve learned something about 3D printing today. While you’re here, why don’t you treat yourself to some new jewelry and share your love of all things 3D printing with your family and friends today!